Intro

Explore the process of creating machines that do…nothing! This activity encourages creative engineering and helps children learn the vocabulary and processes to constructing a project. With no set direction, there is no pressure to complete a design—simply fun and learning!

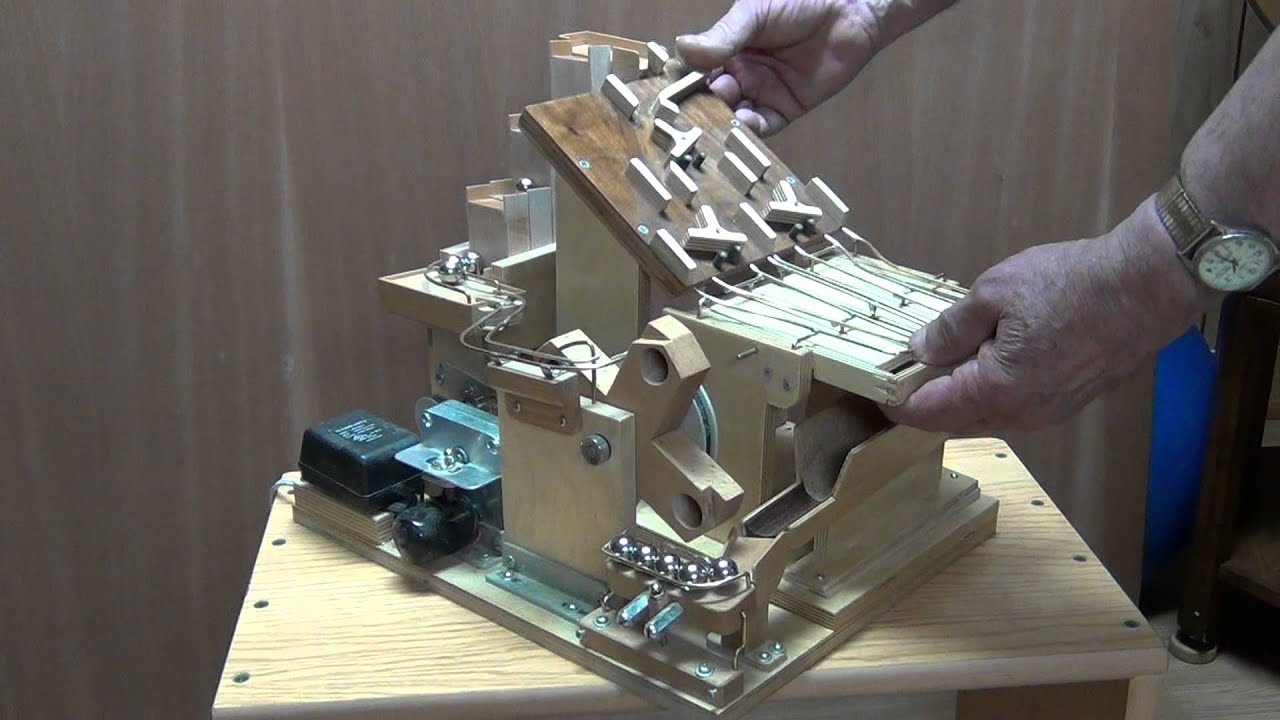

Interesting machines that do nothing. 'Denha's Channel' is a popular Japanese blog. Share on Facebook Email This Video. Daily Headlines. The ellipsographs housed at the museum are far from 'do-nothing' machines. They are precisely engineered drawing devices used by practitioners from the late 19th to the mid-20th century to produce accurate and, to many eyes, beautiful technical drawings. This is mechanical engineering. Each machine illustrates a different example of the basic machine elements used in mechanical engineering. For example, the last machine used a four-bar mechanism to lift the ball bearings. The catapult was controlled with ratchet cam. A wonderful collection of beautifully executed simple machines.

Set Up ideas

Chinese casino game. Provide a variety of materials for children to utilize in their machines. This is a great time to bring out all those leftover doodads that you haven't found a use for!

Let's Get Started

For this activity, you'll need the book, 'The Do-Nothing Machine' by Sharon MacDonald. In addition, you'll also need glue and tape, as well as several disposable and recyclable construction materials such as cardboard boxes, craft rolls or paper towel rolls, wood scraps, etc.

STEP 1

Read the book 'The Do-Nothing Machine' to the child or group. Discuss John's machine and how he had fun in the process of creating it even though it did not have a purpose.

STEP 2

Display the variety of materials gathered together for the project and challenge the children to each build a machine without worrying about whether it does anything.

STEP 3

Support the children through their creative process by noting specific aspects of their work and by using appropriate engineering terminology. Assist in cutting any pieces as necessary.

STEP 4

Once the children have completed their machines, have a show and tell so that the children can admire and discuss each other's do-nothing machines.

As they create their structure, speak with the children using the vocabulary of engineering. Make an effort to use some of the following words: construct, hypothesis, adjust, build, analyze, stability and structure. Learning these words will help the children use those skills when doing other projects.

Tips and Tricks

The more unique materials that you can provide for the children, the more interesting creations they will make! Be sure to ask plenty of questions about children's do-nothing machines and encourage their work.

Follow up Activity

While this activity encourages spontaneity and creativity, children should also learn how to create and stick to a plan. Encourage children to first draw a machine and then create it with the materials provided.

The 'Do Nothing' Machine or Minimizer Test (colorful nicknames for the Standard Timing Model) is our mechanical skills assessment device used to identify mechanical skills and competencies when hiring Maintenance Professionals, Machine Operators, Electro-Mechanical Personnel, Assemblers and Technicians. There are varying degrees of assessment difficulty depending on the position you're hiring for. For example, the assessment protocols for a Maintenance Mechanic Position are more challenging than the assessment protocols for a Machine Operator position.

The process identifies many mechanical skills, which collectively can be characterized as 'Mechanical Troubleshooting Ability.'�

Overly Complex Machines That Do Nothing

This process quantifies mechanical skills and competencies that traditional aptitude tests are not designed for and can't identify.

In addition to identifying and measuring pre-existing skills for both Maintenance and Operator positions, the program also identifies mechanical aptitude in individuals that have not yet been properly trained. Our clients use this capability when they hire entry level team members that must be trained internally. Aptitude translates directly to trainability.

Lower the Risk & Cost of Hiring by Identifying Skills Prior to Hire

Machines That Do Nothing

As the skills shortage grows more acute each year and margin pressures mount it's more critical than ever before to make the right hiring decision. Our validated Manufacturing Skills Assessment Program, using portable assessment machines and a Hands-On, Performance-Based methodology, identifies the most skilled, most capable, and most trainable candidates and incumbents.